In house manufactured

Hulls

Naked hull in house manufactured

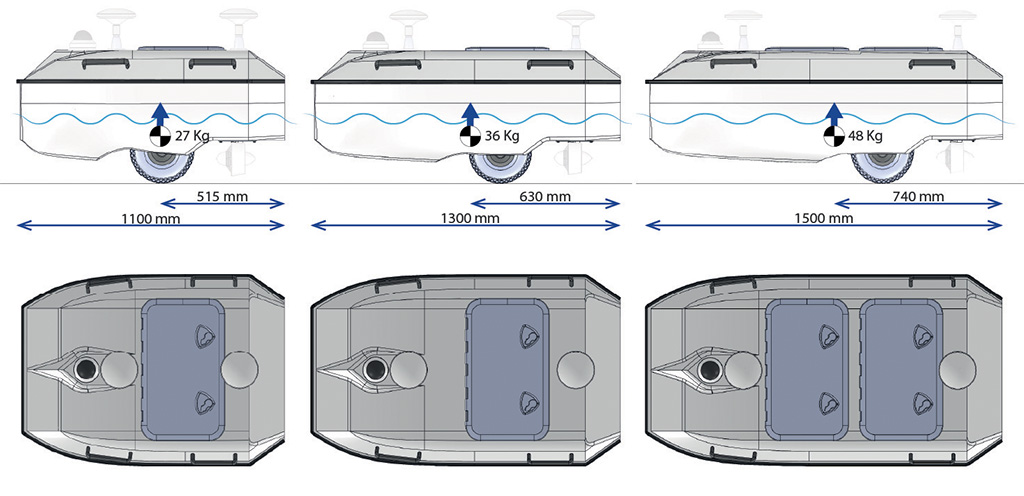

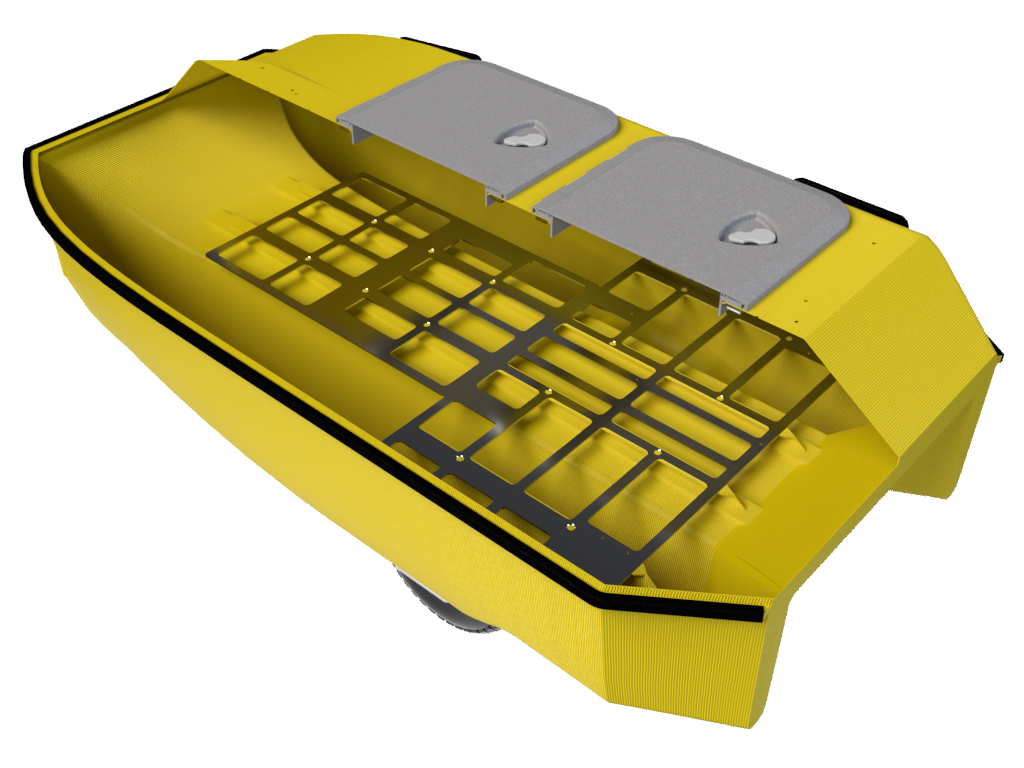

Our 3D printed naked hull, in-house manufactured, boasts integrated transportation rubber wheels, a motor adapter plate for BlueRobotics T500 and T200, access hatch(es), and a rubber steel-reinforced fender. Additionally, it features a couple of T-rails in the bottom central part, plastic handles, and an internal steel deck. This versatile and durable hull is designed to meet your specific USV requirements, offering exceptional customization possibilities and robust construction for various marine applications.

Technical details

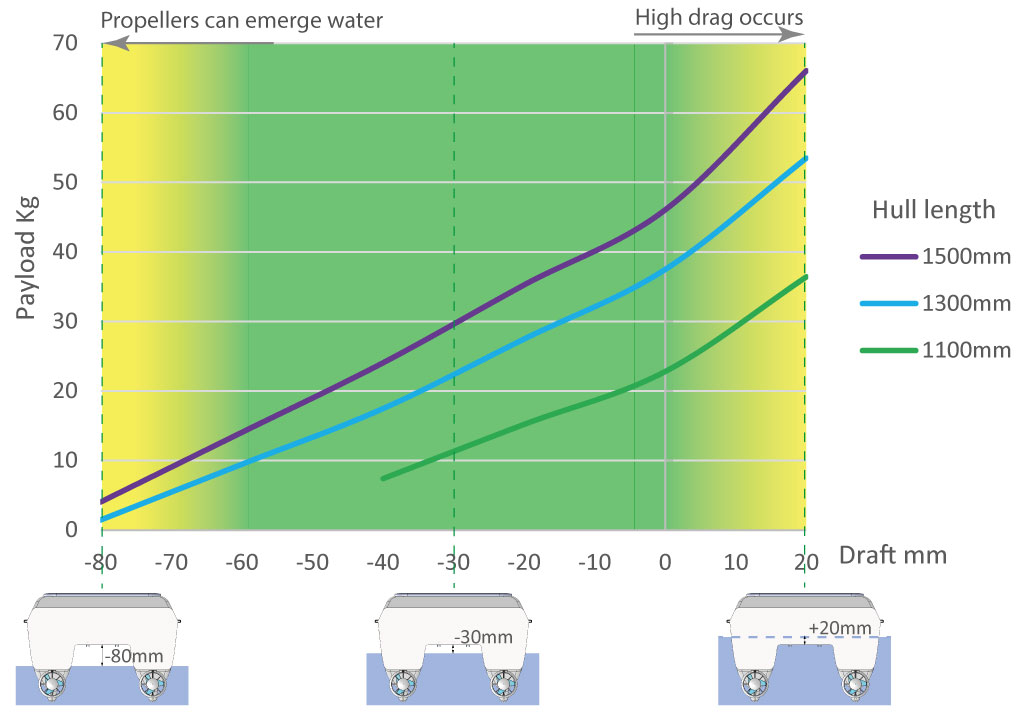

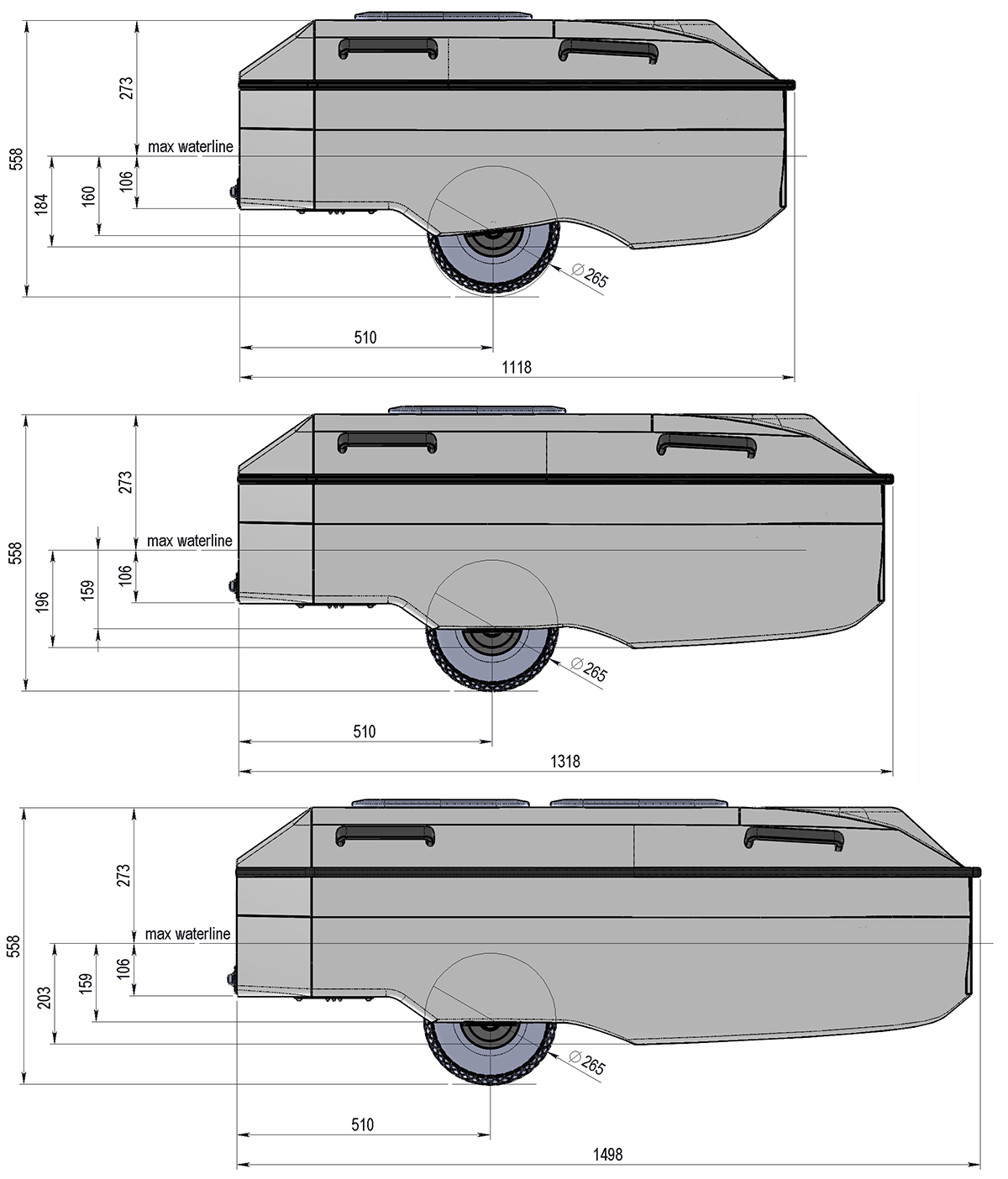

Useful load (Kg) vs Draft

The material

Our hull production begins with the use of technopolymer virgin granules, ensuring high-quality material for durability and strength. To bring this vision to life, we employ a state-of-the-art 3D printing machine specifically designed and optimized for this product. This custom-built machine allows us to precisely control the printing process, resulting in a seamless and precise hull construction. By utilizing 3D printing technology, we achieve greater design flexibility, enabling customization and rapid prototyping. The combination of technopolymer granules and our specialized 3D printing machine ensures that our hulls are produced with the utmost precision, reliability, and efficiency.

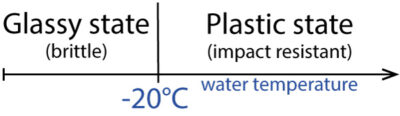

The plastic used in our hulls exhibits a glass transition at -20°C. This means that even at water temperatures, the material remains in a plastic state, ensuring exceptional strength and durability for superior performance and reliability.

In case you are concerned about the durability of our 3D printed hulls

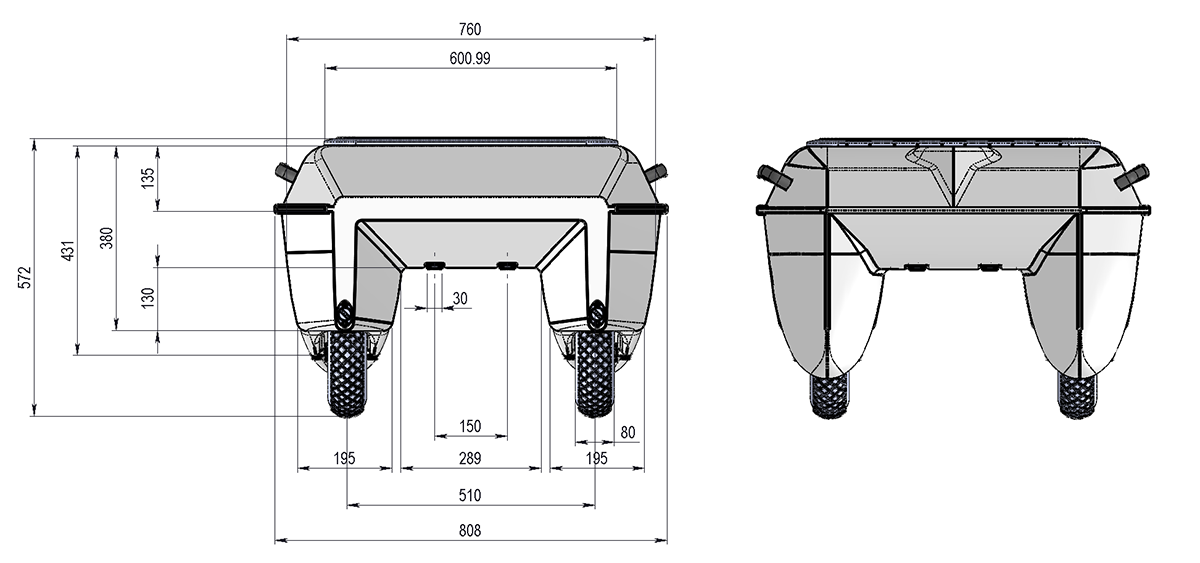

Pneumatic wheels

Our hull design features the integration of two pneumatic rubber wheels, offering effortless maneuverability for a single operator. These wheels are strategically placed to ensure easy movement and transportation of the USV. With their shock-absorbing properties, they provide smooth rolling over various terrains, including rugged surfaces and uneven landscapes. The ergonomic design allows for quick and hassle-free deployment, making it convenient to transport the USV to and from the water.

The integration of these pneumatic rubber wheels enhances the usability and accessibility of our USV, providing efficient mobility for users and minimizing the logistical challenges associated with its handling.

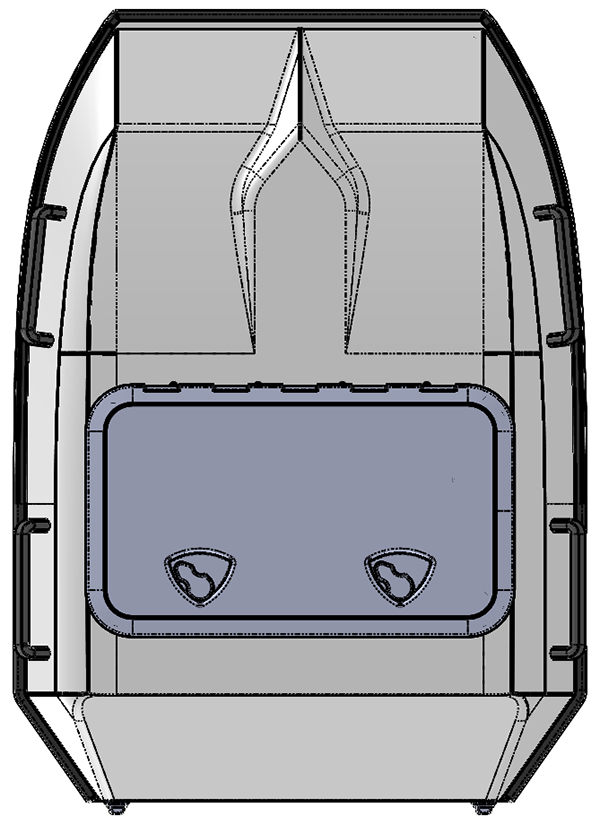

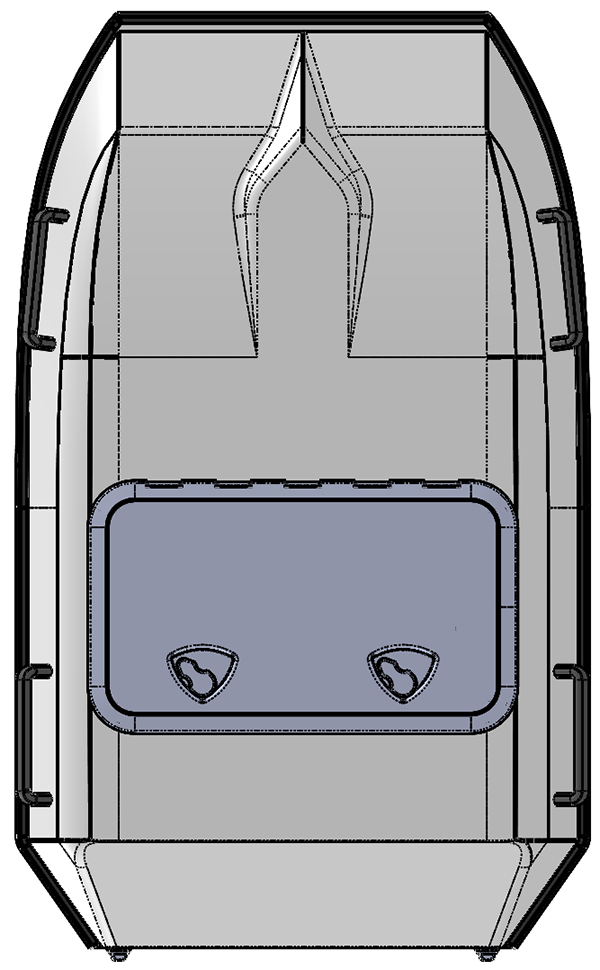

Standard nautical waterproof hatches

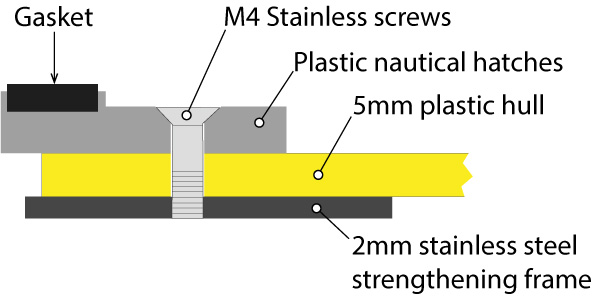

Our hull design incorporates integrated waterproof nautical hatches, adding a crucial element of functionality and convenience. These hatches are specifically designed to provide a secure and watertight seal, safeguarding the contents within the hull from water intrusion. Their robust construction and reliable sealing mechanism ensure protection against harsh marine environments and adverse weather conditions.

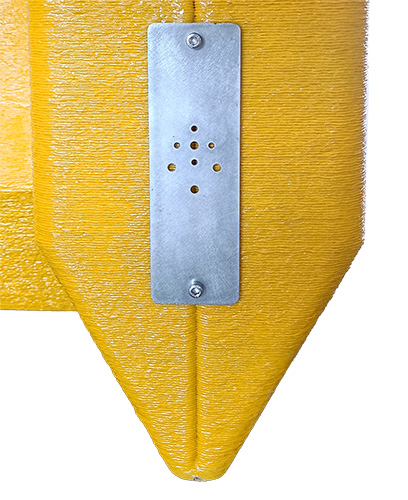

To enhance rigidity and robustness, each hatch is equipped with a stainless steel counterplate measuring 2mm in thickness. This additional layer of reinforcement adds structural strength to the hatches, ensuring durability and resilience in demanding marine conditions.

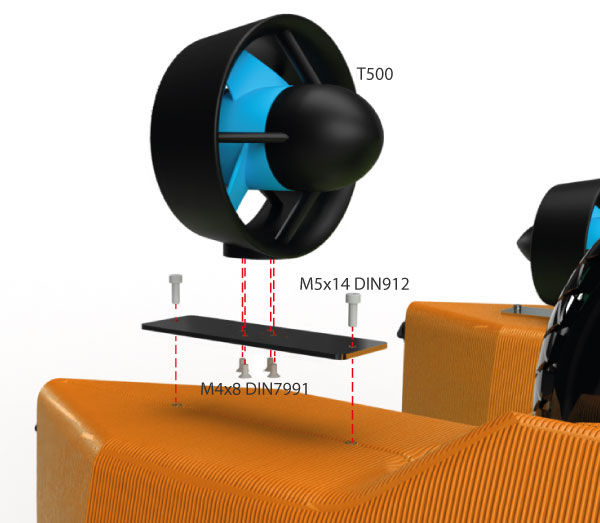

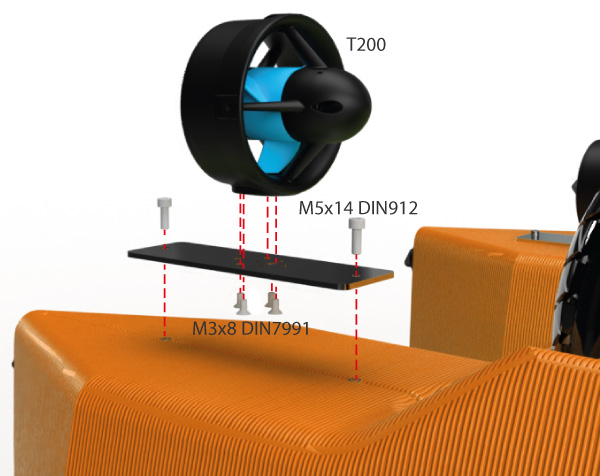

Designed to accommodate two T500 or T200 motors.

Our USV is equipped with a stainless steel plate adapter designed specifically to mount the T500 or T200 thrusters. This adapter serves as a robust and reliable interface between the thrusters and the hull. Crafted from high-quality stainless steel, it offers exceptional strength, corrosion resistance, and durability, ensuring optimal performance in various aquatic environments. The precision-engineered design ensures a seamless fit, providing secure attachment and stability for the thrusters. With the stainless steel plate adapter, users can easily install and integrate the T500 or T200 thrusters onto the USV, enabling efficient propulsion and maneuverability for a wide range of marine applications.

Blue Robotics T500

With the T500 thruster, our USV boasts an impressive 32kg of thrust, making it exceptionally powerful and dynamic on the water. This substantial thrust allows for swift acceleration and efficient maneuverability, enabling the USV to reach speeds of up to 3m/s. Whether it’s navigating through challenging currents or covering large distances swiftly, the T500 thruster provides the necessary propulsion for a wide range of maritime tasks. Its robust design and high-performance capabilities ensure reliable operation even in demanding conditions. With this level of power and speed, our USV equipped with the T500 thruster offers unmatched performance and versatility for various marine applications.

Blue Robotics T200

Equipped with the T200 thruster, our USV possesses a substantial 10kg (16V) of thrust.

Featuring the T200 thruster, our cost-effective USV offers a commendable 10kg (16V) of thrust, providing sufficient power to propel a fully loaded USV at a speed of 1m/s. This propulsion capability ensures reliable and efficient movement, making it a practical choice for various applications where high speeds are not a priority.

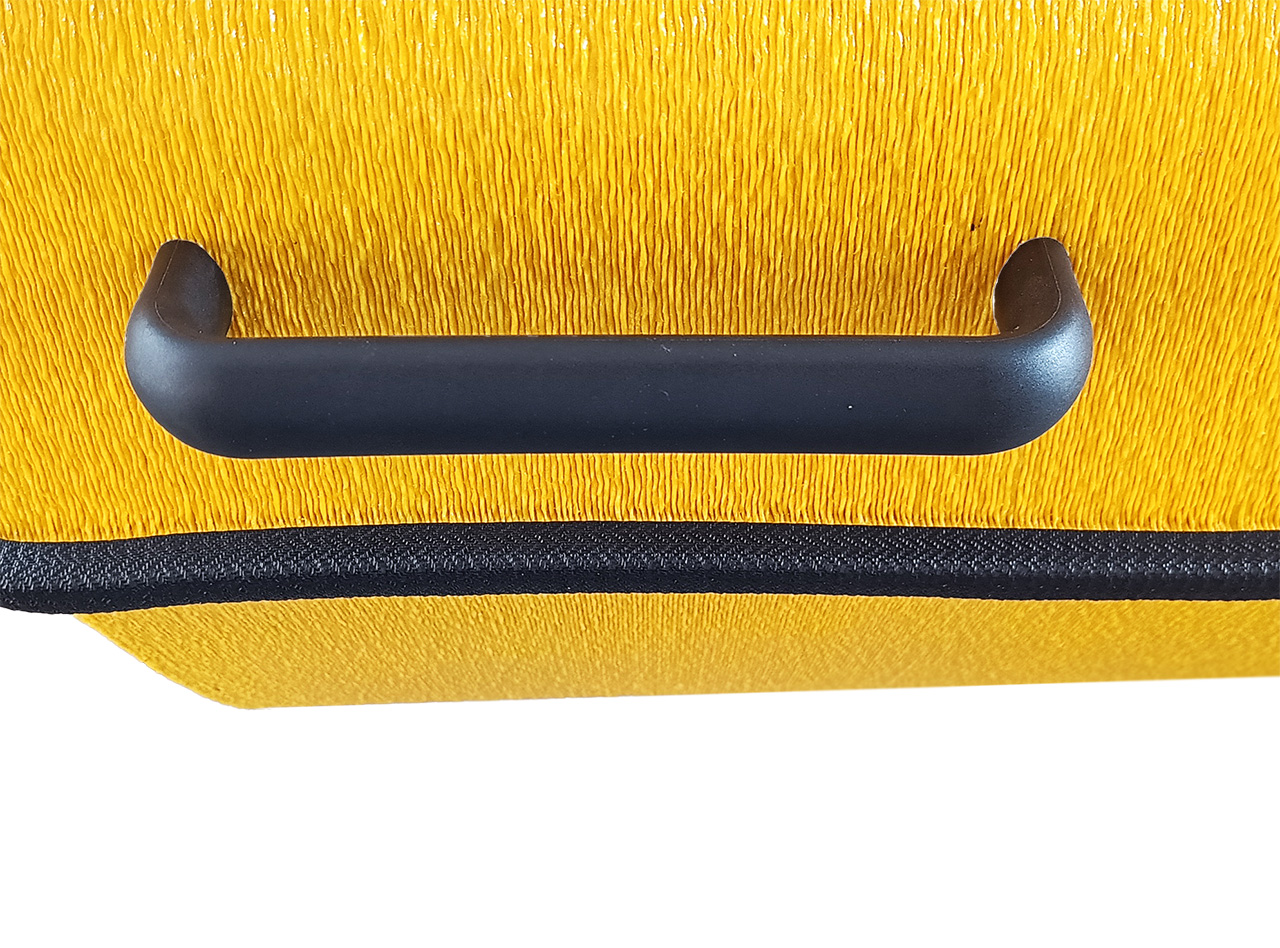

High-strength handles

Our USV is equipped with four high-resistant handles, providing convenient and secure grip points for easy transportation. These handles are designed to withstand heavy loads and offer reliable support, ensuring hassle-free maneuverability of the USV during deployment and retrieval.

To enhance rigidity and robustness, each hatch is equipped with a stainless steel counterplate measuring 2mm in thickness. This additional layer of reinforcement adds structural strength to the hatches, ensuring durability and resilience in demanding marine conditions.

Plastic fender steel reinforced

Our hull design features a plastic fender reinforced with steel, providing enhanced protection and durability. This combination ensures that the hull can withstand impact and abrasion, safeguarding the integrity of the vessel and increasing its longevity in demanding marine conditions.

To enhance rigidity and robustness, each hatch is equipped with a stainless steel counterplate measuring 2mm in thickness. This additional layer of reinforcement adds structural strength to the hatches, ensuring durability and resilience in demanding marine conditions.

Internal steel decks

Our hull design incorporates two stainless steel grids that serve as secure platforms for mounting and locking all electronic components. These grids, made with 3mm thick stainless steel plates, not only provide a sturdy foundation for the equipment but also enhance the overall rigidity of the hull structure. The grids are securely fastened in position using an array of screws, ensuring stability and preventing any unwanted movement. This robust mounting system offers reliable protection for sensitive electronics and allows for easy access during installation, maintenance, or upgrades. The combination of stainless steel grids and locking screws ensures the utmost durability, security, and functionality for the electronic setup on our hulls.

To enhance rigidity and robustness, each hatch is equipped with a stainless steel counterplate measuring 2mm in thickness. This additional layer of reinforcement adds structural strength to the hatches, ensuring durability and resilience in demanding marine conditions.

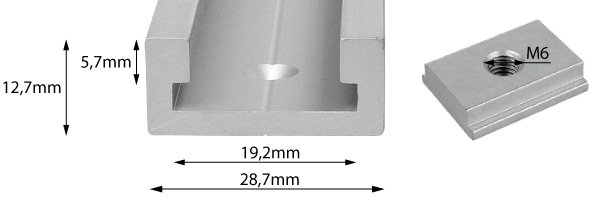

T rails

Our USV is equipped with four high-resistant handles, providing convenient and secure grip points for easy transportation. These handles are designed to withstand heavy loads and offer reliable support, ensuring hassle-free maneuverability of the USV during deployment and retrieval.

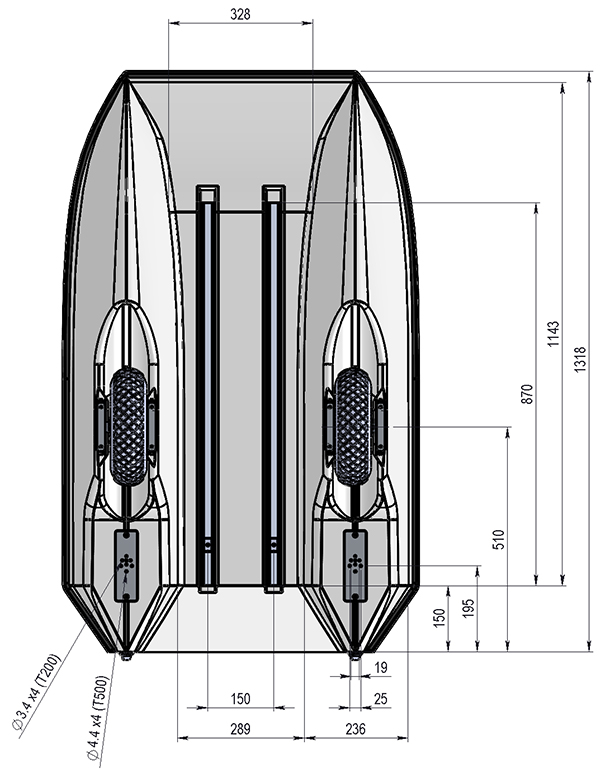

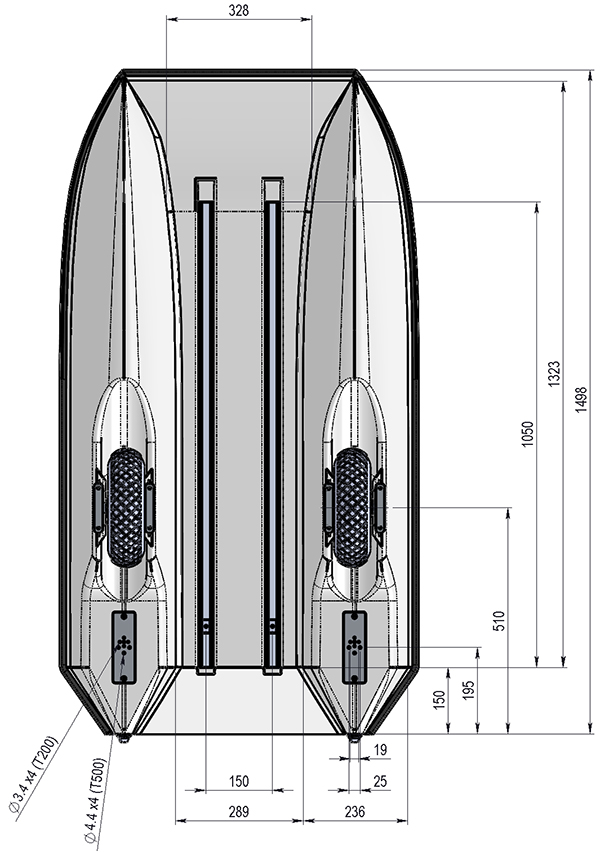

Our USV features two anodized aluminum T-nut rails positioned within the central tunnel, spaced 150mm apart. The anodized aluminum construction ensures durability and corrosion resistance, with the T-nut design allowing for effortless positioning and adjustment of the payload. This versatile payload attachment system enhances the functionality and adaptability of our USV for diverse marine applications.

These rails provide a versatile and secure attachment system to accommodate a wide range of payloads, such as :

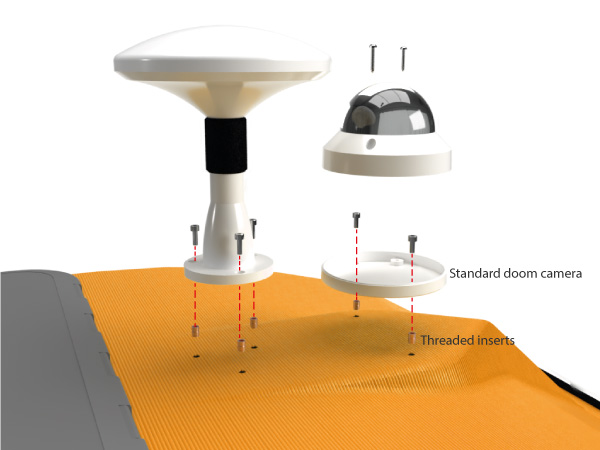

Bow upper deck

The upper bow side of our vessel provides a convenient mounting location for a dome camera, offering a first-person view (FPV) perspective. This elevated position allows for an optimal vantage point, capturing clear and immersive footage. Additionally, the plane on the upper bow side serves as an ideal spot to install an antenna mount, ensuring excellent signal reception and transmission capabilities. With these features in place, operators can enjoy real-time FPV streaming and maintain reliable communication links, enhancing situational awareness and operational efficiency. The thoughtful design of our vessel accommodates these key elements, enhancing its versatility and functionality for a range of applications.

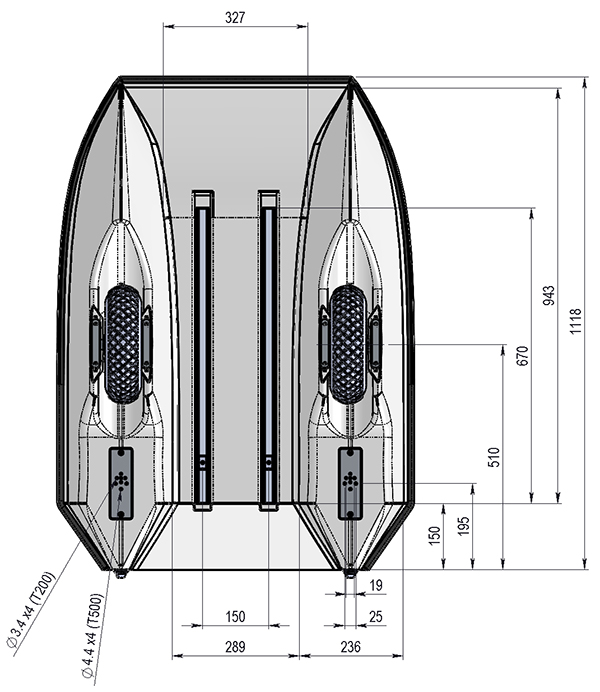

Dimensions

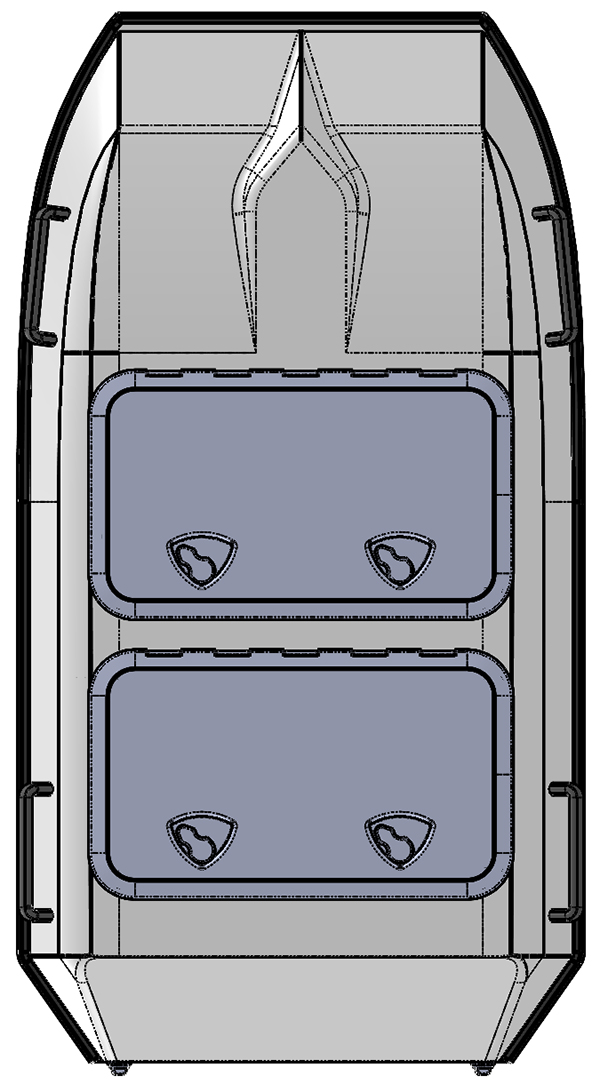

Bottom view

Top view

Side view

Front / back view

Center of pressure

You can conveniently download the 3D STEP file representing the internal volume of our hulls.

These files enable you to visualize and plan the arrangement of your items, ensuring optimal utilization of the internal space. With the downloadable STEP files, you have the flexibility to design and integrate your equipment efficiently.

This resource empowers you to customize and optimize the internal layout of our product to suit your specific needs.